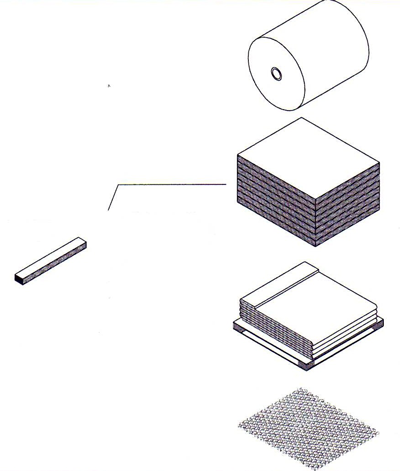

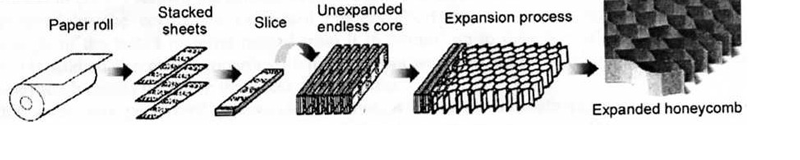

Production

There are 2 basic methods of producing paper honeycomb:

Production of blocks and two steps continuous honeycomb productions

From 2 paper rolls the paper is guided on a glue roller which brings glue lines in the length direction on the paper. The distance between the gluing lines defines the cell sizes of the honeycomb. The 2 paper layers are winded on a big winding drum. If there are about 300 layers on the drum, the paper layers are cut in big block of about 1500 mm length. After this process the big blocks of 1500 mm are cut into small blocks of the exact thickness of the desired honeycomb thickness, for example 33.0 mm for the door industry. These small blocks are glue to each other, so you will have continuous honeycomb. On 1 pallet of 100 x 120 x 100 cm you will have after expanding about 1000 m2 of honeycomb. If the clients do not need continuous honeycomb, the blocks are not glued together.

The advantage of this way of production:

- less as possible tolerance

- very stable cell size

- no gluing pollution

- also block productions

- smaller batches

- smoother surface of the honeycomb edges

2) One step continuous honeycomb production

From 2-4-6-8 or12 paper rolls the paper is guided on a glue roller which brings glue lines in the length direction on the paper. The distance between the gluing lines defines the cell sizes of the honeycomb. The 2-4-6-8 or 12 paper layers are guided through a cutting knife which cut the paper layers directly on the correct thickness of the desired honeycomb. After the cutting knife the pieces are glued together to an continuous paper honeycomb. The cutting speed can vary from 200 up to 700 cuts per minute.

The advantages of this way of production:

- higher production output

- less production waste

- real continuous honeycomb (no gluing stripes)

- less m2 per pallet (layers are less compressed)

- large paper width (up to 3000 mm)

Both production methods are already done from the sixties of the last century and are developed with the latest technologies more and more.